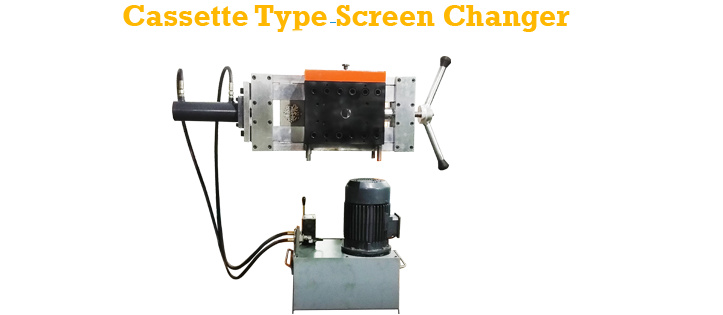

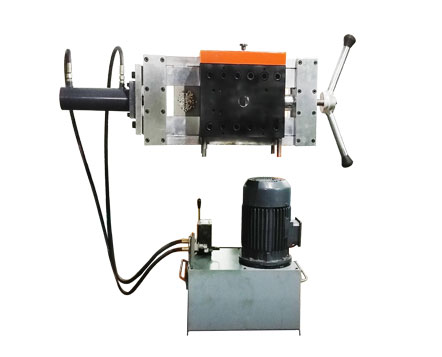

Cassette type Screen Changer

Technical Specification

*Design and Technical Specification should change prior to information

| Sr No. | Model | Power in K.W. | Filter size in MM |

|---|---|---|---|

| 1. | NOCT-65 | 2.4 K.W. | Dia.65 |

| 2. | NOCT-80 | 3.2 K.W. | Dia.80 |

| 3. | NOCT-100 | 4.0 K.W. | Dia.100 |

| 4. | NOCT-125 | 6.0 K.W. | Dia.125 |

Application:

- PET Box Stripping Plant

- PP Box Stripping Plant

- PET Sheet Plant

- Multi Filament Plant

- Lumps Plant

- PVC Recycling Plant (Special Design)

- Sheet Plant

Advantages:

- Filter remove the impurities and prevent the damages of Die.

- Filter improves the quality of final product.

- It is Hydraulic operated so plant output will we increased compare to manual operating. So, save the time and power with same output.

- Eliminate the idle time and easy to operate.

- special arrangement given in breaker plate so, increase the mesh life and save money.

- Easy maintenance.

Optional Availability:

- Barrel & Die side fitting arrangement along with heaters and fasteners.

- Extra Heaters.

- Extra filters.

- Special design for PVC and Engineering Plastic Plant.

- Accumulator system will provide if required.

- Heating Panel will provide for Screen changer heating.

- Pressure Transducer system will provide for improves life of Extruder and screen changer and to avoid accident.

- Special timing panel.

- Fabricated / Wheel mounted stand for support / movement of Screen Changer.

- Detachable Breaker Plate designed also available for special application.

Call Us: +91 8000703753

Call Us: +91 8000703753  Email: sales@orangeplasticmachinery.com

Email: sales@orangeplasticmachinery.com