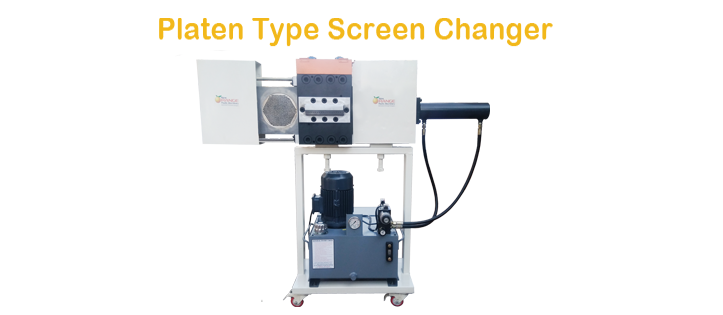

Platen type Screen Changer

Technical Specification

*Design and Technical Specification should change prior to information

| Sr No. | Model | Power in K.W. | Filter size in MM |

|---|---|---|---|

| 1. | NOP-105 | 3.2 K.W. | Dia.105 |

| 2. | NOP-125 | 3.6 K.W. | Dia.125 |

| 3. | NOP-155 | 4.8 K.W. | Dia.155 |

| 4. | NOP-185 | 5.2 K.W. | Dia.185 |

| 5. | NOP-205 | 6.2 K.W. | Dia.205 |

| 6. | NOP-225 | 6.6 K.W. | Dia.225 |

| 7. | NOP-250 | 8.8 K.W. | Dia.250 |

Operation:

Stop the Plant and change the filter station with the help of Hydraulic Cylinder. Now, start the Plant. Remove the old chocked mesh and put new mesh is in it while running Plant / Extruder.

Application:

- Recylcling Plant

- Filler Plant

- Master Batch Plant

- Lamination Plant

- Lumps Plant

- PVC Recycling Plant (Special Design)

- Sheet Plant

Advantages:

- Filter remove the impurities and prevent the damages of Die.

- Filter improves the quality of final product.

- It is Hydraulic operated so plant output will we increased compare to manual operating. So, save the time and power with same output.

- Eliminate the idle time and easy to operate.

- special arrangement given in breaker plate so, increase the mesh life and save money.

- Easy maintenance.

Optional Availability:

- Barrel & Die side fitting arrangement along with heaters and fasteners.

- Extra Heaters.

- Extra filters.

- Special design for PVC and Engineering Plastic Plant.

- Accumulator system will provide if required.

- Heating Panel will provide for Screen changer heating.

- Pressure Transducer system will provide for improves life of Extruder and screen changer and to avoid accident.

- Special timing panel.

- Fabricated / Wheel mounted stand for support / movement of Screen Changer.

- Detachable Breaker Plate designed also available for special application.

Call Us: +91 8000703753

Call Us: +91 8000703753  Email: sales@orangeplasticmachinery.com

Email: sales@orangeplasticmachinery.com