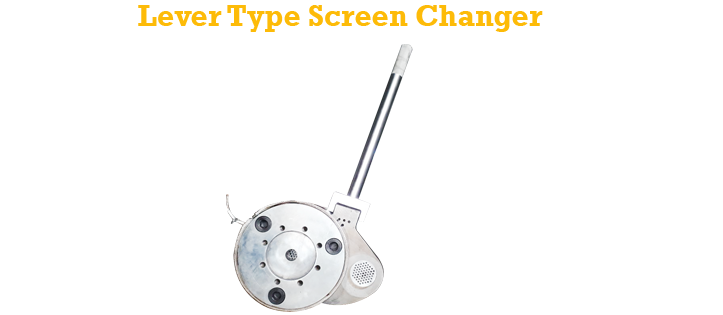

Lever type Screen Changer

Technical Specification

*Design and Technical Specification should change prior to information

| Sr No. | Model | Power in K.W. | Filter size in MM |

|---|---|---|---|

| 1. | NOL-30 | 1.8 K.W. | Dia.30 |

| 2. | NOL-40 | 2.0 K.W. | Dia.40 |

| 3. | NOL-50 | 2.7 K.W. | Dia.50 |

| 4. | NOL-75 | 3.5 K.W. | Dia.75 |

| 5. | NOL-90 | 4.0 K.W. | Dia.90 |

Operation:

Stop the Plant and change the filter station with the help of Handle. Now, start the Plant. Remove the old chocked mesh and put new mesh is in it while running the Plant.

Application:

- Pipe Plant

- Mono Layer Plant

- Multi Layer Plant

- Lamination Plant

- Co-extrusion Plant

- Sheet Plant

- Sutli plant

- Mono Filament Plant

- Pen & Tubing Plant

Advantages:

- Filter remove the impurities and prevent the damages of Die.

- Filter improves the quality of final product.

- Eliminate the idle time and easy to operate.

- Easy operating – change the handle only.

Optional Availability:

- Barrel & Die side fitting arrangement along with heaters and fasteners.

- Extra Heaters.

- Extra filters & Breaker Plates.

- Heating Panel will provide for Screen changer heating.

- Pressure Transducer system will provide in adopter for improves life of Extruder and screen changer.

- Fabricated / Wheel mounted stand for support / movement of Screen Changer.

Call Us: +91 8000703753

Call Us: +91 8000703753  Email: sales@orangeplasticmachinery.com

Email: sales@orangeplasticmachinery.com